PEKAT VISION contains the right set of self-learning tools.

These tools can be combined and interwoven with a scripting code. Our experience has shown that exactly these tools together can tackle practically any vision task in manufacturing.

Learn how to connect to a camera, integrate e.g. with Labview, calculate statistics and much more on our github.

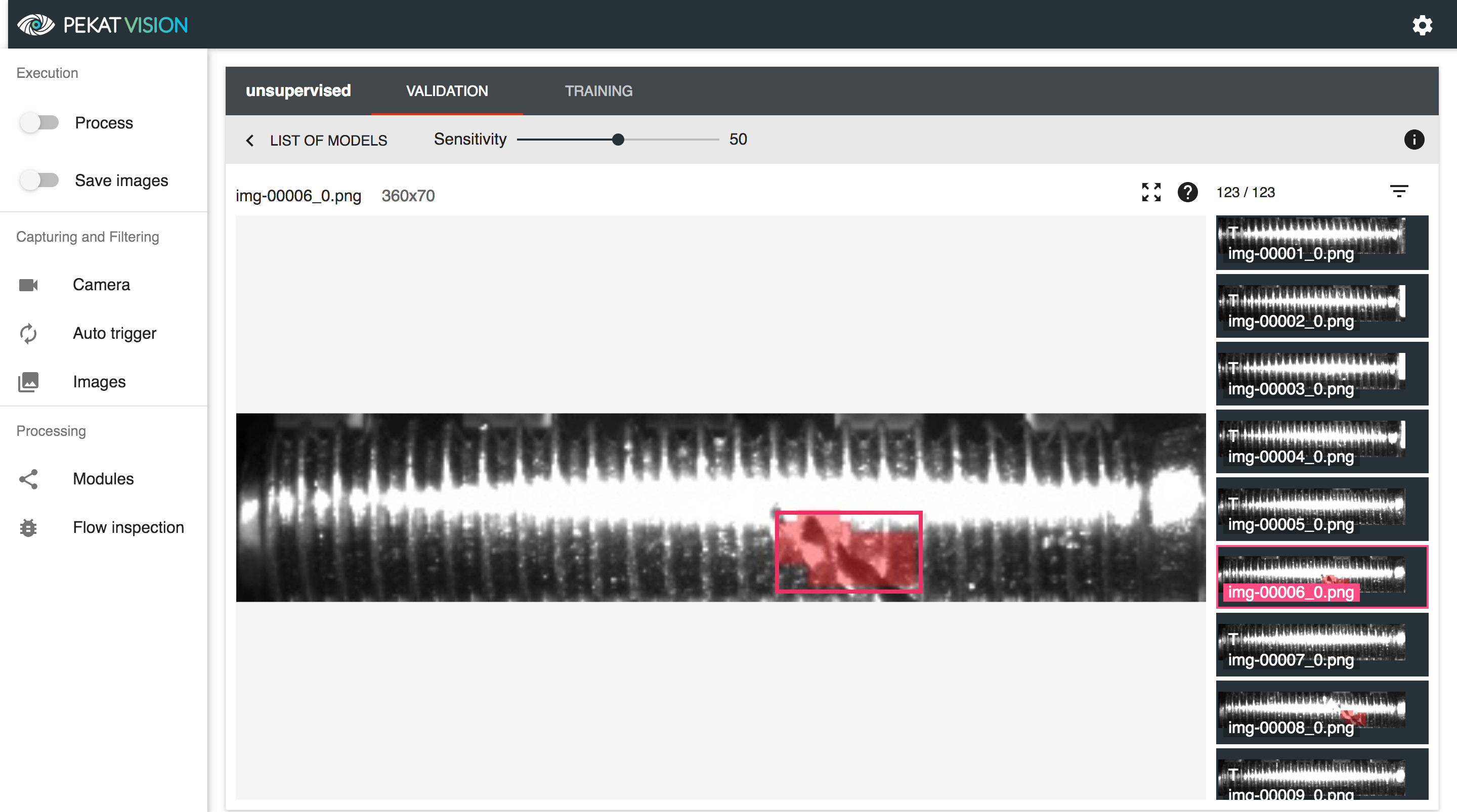

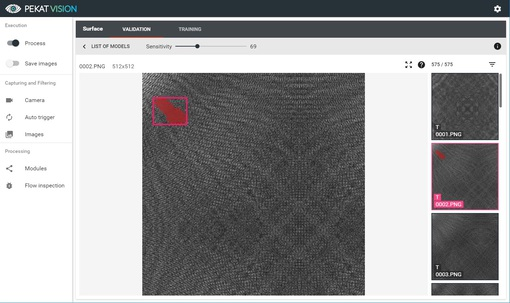

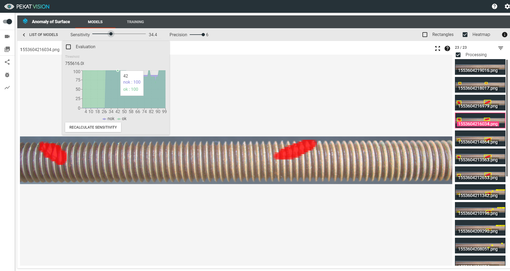

Unsupervised anomaly detector can be trained by positive (error-free) examples. It is enough to provide just a few example images. It is able to inspect stable objects or even completely unstable surfaces like deformed textile with pattern.

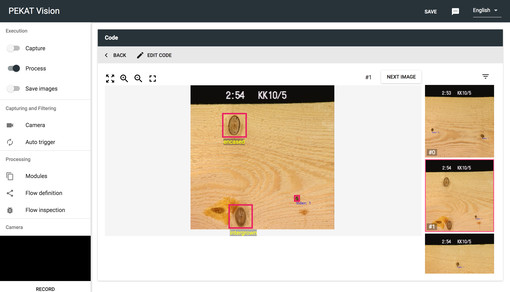

Object detector and classifier can find objects with unstable shape - e.g. knots on wood. It doesn't even matter if the objects are rotated.

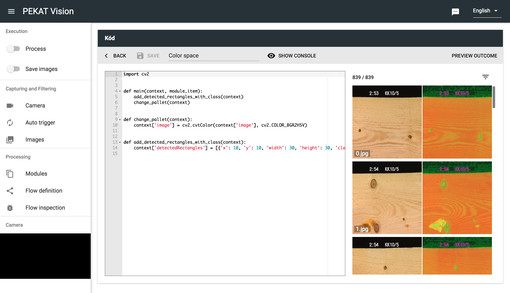

Python code gives you high flexibility. You can e.g. preprocess images (e.g. with OpenCV and Numpy), add custom logic or even call external interfaces.

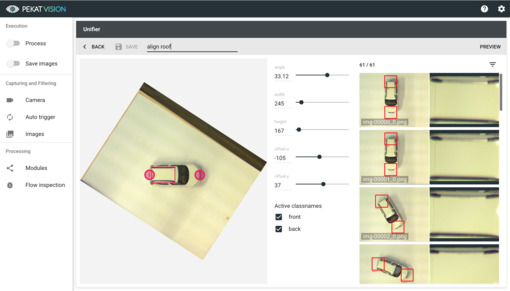

Unifier can be used when objects which are to be inspected are rotated or the position is scattered in the images. Unifier unifies the position and rotation of the objects in the images for further processing.

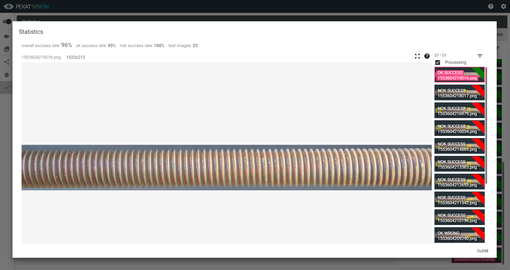

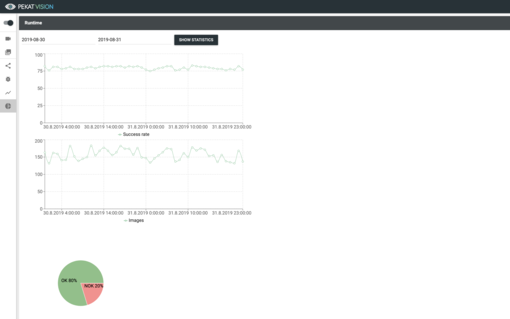

Statistics calculate how successful the application evaluates the image and what is the false positive and false negative rate.

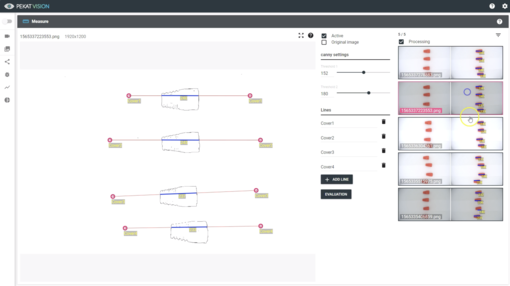

Measurement module serves for simple measurement of dimensions of object.

Supervised surface check is a tool which can be trained to find defects on a completely heterogeneous surfaces. Example of such defects: rust, abrasion, leakage etc.

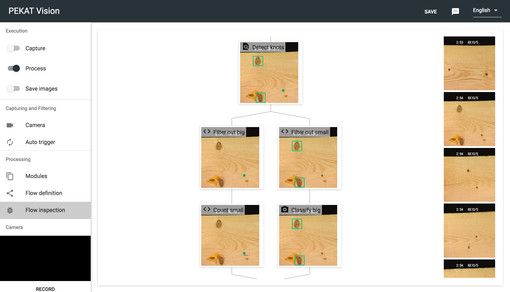

Inspection modules can be combined to a complex flow and even interwoven with custom image preprocessing or scripting code.

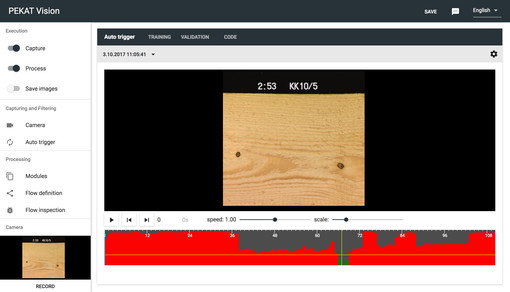

Auto-Trigger can be simply trained to automatically capture images in the right moment without any necessary integration with the machine or assembly line.

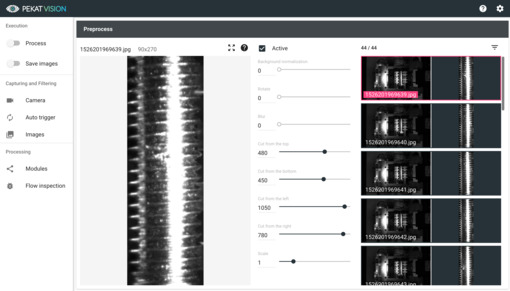

Preprocess module is a tool for easy image editing before the next processing. It allows rotation, cropping, scaling, and background normalization.

Auto sensitivity is a part of the anomaly detection module and determines the best sensitivity value and can ideally find the border between good product and defective product.

Runtime statistics shows statistics of OK and NOK images sent from API according to specific date and time you choose.